There are more pictures in my gallery.

Bud

First thing I learned, as others have too, is that our beloved dune buggy bodies are not symmetrical therefore this box had to be built one piece at a time in the buggy. I started with the bottom/seat piece and cut it in the the shape to fit the seating area. Second piece was the back. While this might sound simple, remember what I said about a lack of symmetry. Third piece was the front. I knew I wanted the box to fit snug but not tight (so I could remove it but it wouldn't slide around) so I mocked up the front piece to have the same angle as the roll bar. Additionally, I wanted this box to be sturdy so I notched along the bottom edge of the front/face piece to fit over the bottom. Additionally, I wanted the sides and back pieces to sit above the edge of the seating area and I would "groove" the top to fit over them creating a water tight fit (you'll see this in later pictures. I used 3/8 inch sanded plywood for the box base, back, and sides. I used 3/4 inch sanded plywood for the front/face and top. In order to get the front/face piece to fit between the roll bar and the tire wells, I have to bevel the edges around the tire well. Here are some pictures:

Next came the side pieces. I again "grooved" the front/face piece for the sides to fit and secure to the front more securely. Each side is VERY different from one another.

You can see in this picture how the sides and the back extend higher than the front. The top will fit over the sides and back creating a tight fit:

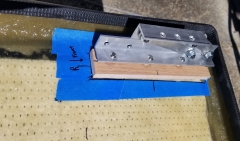

In these pictures you can see the multiple grooves and bevels cut into the front piece for the base, the sides, and fitment around the wheel wells.

Next step was to enclose the interior by building "wheel wells" around the wheel wells.

The top: there are multiple details about the top, first I used a router to cut a groove all the way around the interior of the top for the sides and back to fit into. What I didn't do is cut the groove past the front edge of the side. This way you won't see the groove when the top is down. Next was I had to grind down the trialing edge (back edge/lip of the top - edge over the motor) down so that when the top was closed it wouldn't hit the body. Oh in case you didn't know the body isn't flat across the back. Lastly I used cabinet hinges, instead of a piano hinge on the front, so that you wouldn't see them.

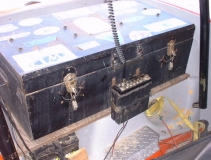

I added a little personal touch to the top of the top. I decided I wanted tie downs in case I needed to carry something that didn't fit in the box. To protect the finish on the lid I added oak slats. The tie downs are marine latch rings. Additionally I wanted to be able to lock the box so I added a marine flat latch (lockable). I have no illusions that if someone wants in the box they could "spring" the lid.

To give the box a little more finished look I glued in cheap indoor/outdoor carpet from Lowes (the stuff that they cut from a huge roll).

I painted the whole box with Krylon gloss black and then added about six to eight layers of Kylon clear on the top and front/face. After eight years the finish has held up pretty well and the box has met all my expectations.